Don’t let data go to waste – How to identify and utilize anomalies?

Modern industrial equipment and processes generate data around the clock, every second. In a large amount of data, anomalies also occur. How can such anomalies be identified and utilized?

The continuous stream of data contains valuable information, for example about the operation of devices and other critical aspects of the process. But how can this often massive and complex amount of data be transformed into concrete benefit?

From simple statistical methods to in-depth techniques

Simple statistical methods such as mean, median, and variance can provide a first impression of the data structure and possible anomalies. Visualization is also an effective tool: charts and graphs can reveal trends and anomalies that are easily overlooked in the raw data in tabular form.

Machine learning offers tools and methods that can find structures, patterns, and insights from data that would otherwise be too extensive and complicated for human analysis. Machine learning models can learn to recognize normal data behavior patterns and anticipate potential anomalies that may indicate, for example, equipment failure.

Outlier Detection – Identifying data anomalies

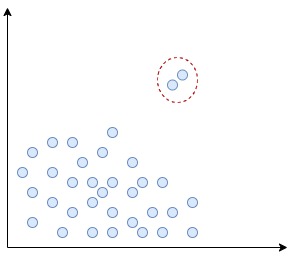

Outlier detection refers to methods used to identify anomalous observations from a dataset. These anomalous values, or “outliers,” are significantly different compared to other observations in the same data.

Anomalies can arise for various reasons. In an industrial environment, anomalous observations can result from measurement errors, abnormal operation of the machine or its user, or they can be signs of some new rare phenomenon. On the other hand, the detection of outliers can also be beneficial in data preprocessing, as outliers can cause biases in data analysis. Removing anomalies may be necessary, for example, before training a machine learning model.

There are numerous methods for detecting anomalies, ranging from statistical methods to complex methods based on neural networks. Anomalies can be the most interesting points in a dataset or just noise, depending on the mechanism of anomalies and the purpose of the data. Therefore, determining the root causes of anomalies is essential for understanding the raw data.

Utilize data and anticipate

The reasons for anomalies can vary, and they may contain hidden signals that indicate equipment failure, unexpected process changes, or other critical disruptions. By identifying anomalies, it is possible to find causes and conditions that, when detected, can lead to corrective actions. This can avoid unexpected equipment failures, production interruptions, and the resulting significant financial losses.

The effective utilization of data in the detection and anticipation of anomalies is critical in the management of industrial processes and equipment. It not only reduces unexpected costs but also enables continuous improvement and efficiency enhancement. In an industrial environment, data is not just numerical information but a valuable resource that provides deep understanding and competitive advantage to those who know how to use it correctly.

Jere Toivonen

Software Engineer

Ida Pellinen

Marketing and Communications Specialist